Wooden Hanger Factory

480+ employees,

250,000 hangers/day

Solar Energy Storage:Creates a constant temperature and humidity environment for your hanger. Guarantee the quality and on-time delivery

Italy Baking Room:Micro electric control, 200 m³ , to ensure the quality and the delivery time is not affected by weather

Electrostatic Constant Temperature Workshop: 800㎡, 6 latest electrostatic spraying lines with double-layered enclosed conveyors cycling,fast dry and high yield rate make the painting hanger surface more beautiful.

Huge Central Vacuuming Tower: Absorb the harmful gas and dust of workshop. Assure the clean, quiet, healthy & efficient work

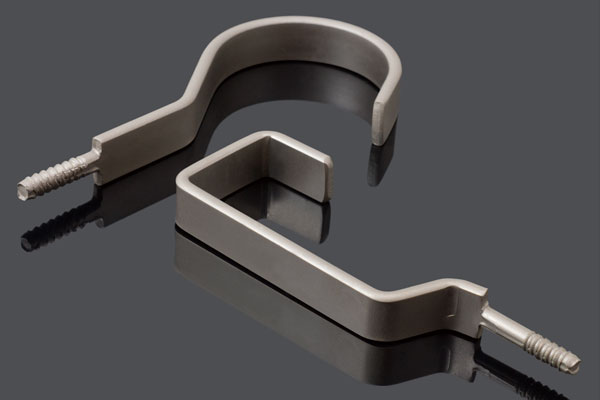

Metal Hanger Factory

560+ employees,

500,000 accessories/day

Dip-Coating Workshop:4 upgraded electrostatic plastic spray lines, environmental, short curing time of coating. finish more sturdy, color more gorgeous

Impulse Welding Workshop:28 punching welding equipments, operated by the qualified technical personnel, assure all hangers are firmly and neatly welded.

Assembly Workshop:Speed and skills are the core assessment indicators for assembly workers every day, month and year, so as to ensure both quantity and quality.

Electroplating Factory

180+ employees,

10 tons accessories/day

Cleansing Workshop: Adopted the newly developed OY-49 normal temperature degreasing and derusting. Promising the products’ anti-corrosion & rust-proof function superior 15-20 times than traditional way. The brightness of the product is sharper.

Hung Workshop : Use “three cleanings + three ventilations” policy, which means keep contaminated items, water, gas cleaned and have wind, light, air ventilated.

Electroplating Workshop : 8 high tech plating lines. High capacity, good quality, low loss, and environmental protection. Up to now, Betterall’s electroplating waste water treatment has reached the national class II drinking water standard.